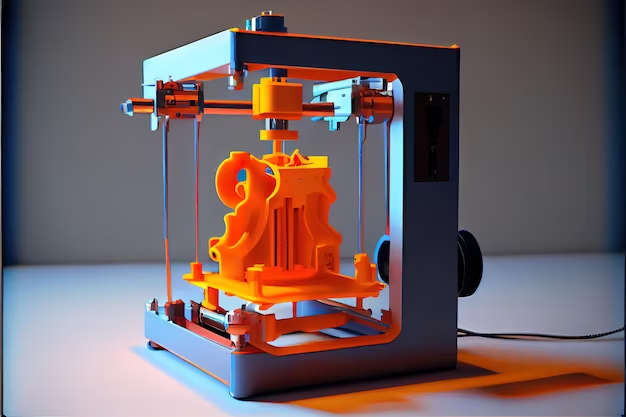

The synergy between Artificial Intelligence (AI) and 3D printing is transforming the manufacturing landscape. While 3D printing has revolutionized production with its ability to create complex structures layer by layer, AI introduces an unprecedented level of precision, efficiency, and innovation. This collaboration is driving advancements that could significantly reshape industries ranging from healthcare to aerospace.

Optimizing Design Processes

One of the most significant contributions of AI to 3D printing is the optimization of design processes. Traditional design often involves trial and error, which can be time-consuming and costly. AI, however, leverages generative design algorithms to explore all possible configurations of a design. These algorithms take into account material properties, manufacturing constraints, and performance criteria, generating optimal designs that human engineers might not conceive. This process not only speeds up design but also leads to innovations that push the boundaries of what’s possible in 3D printing.

Enhancing Print Quality

Print quality has been a persistent challenge in 3D printing. Variations in temperature, material properties, and printer calibration can result in defects. AI addresses this by implementing machine learning models that predict and compensate for potential issues in real-time. By analyzing vast amounts of data from previous prints, AI can adjust parameters dynamically, ensuring consistent quality and reducing waste. This predictive maintenance can foresee equipment failures before they occur, further enhancing reliability.

Material Innovation

AI is playing a crucial role in the development of new materials for 3D printing. Machine learning algorithms can analyze material performance data and predict how new composite materials will behave under different conditions. This capability accelerates the discovery of innovative materials that are stronger, lighter, or more sustainable. For instance, in the aerospace industry, where material performance is critical, AI can help develop composites that meet stringent requirements while reducing weight, thereby improving fuel efficiency and reducing costs.

Speeding Up Prototyping

The prototyping phase of product development can be significantly expedited with AI. Traditionally, creating and testing prototypes is a sequential and iterative process. AI can parallelize and automate much of this work, generating and evaluating multiple prototypes simultaneously. By using AI-driven simulations, manufacturers can quickly assess the performance of different designs under various conditions, drastically shortening the development cycle. This rapid prototyping capability is especially beneficial in industries where time-to-market is a critical factor.

Cost Reduction

AI integration in 3D printing can lead to substantial cost reductions. By optimizing designs for material usage and minimizing errors, AI helps to reduce the amount of raw material needed and the time spent on rework. Furthermore, AI-driven predictive maintenance ensures that 3D printers operate efficiently with minimal downtime, extending the lifespan of the equipment. These efficiencies translate into lower production costs, making 3D printing more accessible and economically viable for a wider range of applications.

Customization and Personalization

One of the most promising areas where AI and 3D printing intersect is in customization and personalization. AI algorithms can analyze user data to create highly customized products tailored to individual needs and preferences. In healthcare, for example, AI can use patient-specific data to design and print custom prosthetics, implants, or even tissue scaffolds that match the patient’s anatomy perfectly. This level of customization enhances the effectiveness of medical treatments and improves patient outcomes.

Enhancing Automation

Automation is a key advantage brought by AI to the 3D printing process. AI can automate not just the printing process but also pre-print and post-print operations. This includes automated preparation of print files, real-time monitoring of the print process, and post-processing activities such as finishing and inspection. By reducing the need for human intervention, AI-driven automation enhances productivity, consistency, and scalability of 3D printing operations.

Driving Innovation in Complex Structures

The combination of AI and 3D printing is particularly powerful in creating complex structures that are difficult or impossible to produce with traditional manufacturing methods. AI can optimize internal lattice structures for strength and weight, enabling the production of components that are both lightweight and incredibly strong. This capability is invaluable in industries such as aerospace, automotive, and biomedical engineering, where structural efficiency is paramount.

The collaboration between AI and 3D printing is setting the stage for a new era in manufacturing. By enhancing design, improving quality, accelerating prototyping, and reducing costs, AI is providing the support that 3D printing needs to realize its full potential. As these technologies continue to evolve and integrate, they promise to unlock unprecedented possibilities and drive significant advancements across numerous fields.

From Our Editorial Team

Our Editorial team comprises of over 15 highly motivated bunch of individuals, who work tirelessly to get the most sought after curated content for our subscribers.